LOLER is an acronym for the Lifting Operations and Lifting Equipment Regulations which were enacted in 1998 to improve workplace safety. Whether you are running a business, employed, or curious about workplace safety, it’s important to understand the LOLER safety standards. In this article, you will learn about LOLER testing for chandelier winches, how the regulations work, safety standards, what LOLER testing covers, and the importance of LOLER testing for chandelier winches.

What’s LOLER?

LOLER is an acronym for Lifting Operations and Lifting Equipment Regulations (enacted in 1998 to tame safety-related accidents in the workplace). They are designed to ensure users observe safety standards for all lifting equipment—including chandelier winches—in the UK. These regulations must be adhered to by all.

What LOLER Covers?

LOLER regulations are designed to promote workplace safety. As such, they cover several aspects—mostly related to lifting operations. They clearly define the responsibility of an employer, employee, lifting equipment owner, and operator.

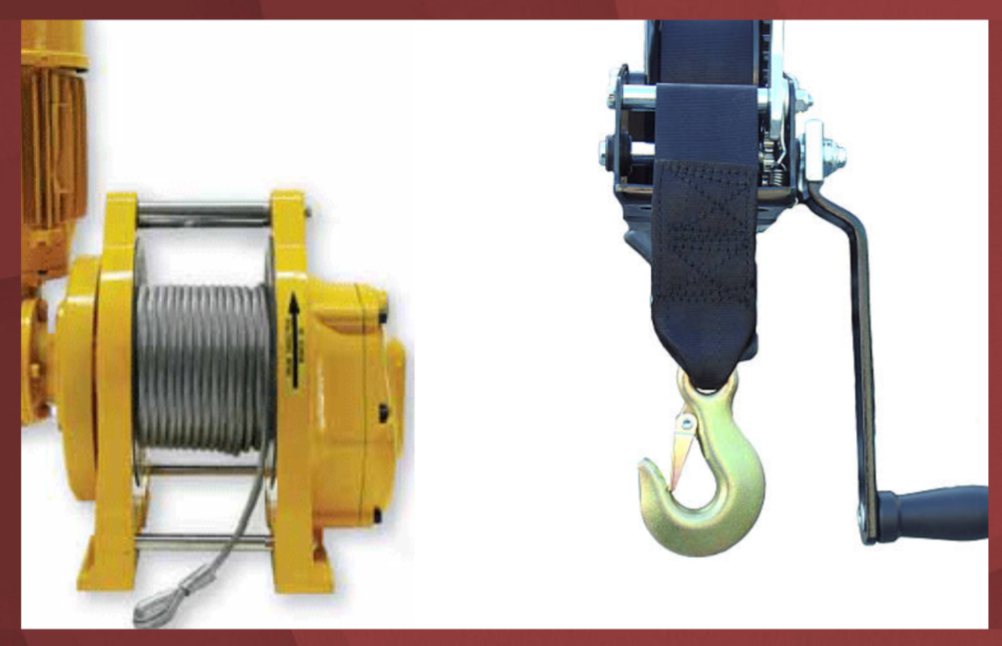

These regulations cover different lifting equipment, machinery, tools, etc. Equipment and machinery like forklifts, ropes, slings, cranes, and hoists must be inspected under the LOLER before they can be used.

Employers should understand all lifting equipment used in their organizations. Additionally, they must ensure that LOLOER regulations are observed whenever lifting equipment and machinery are used.

LOLER Requirements

Under LOLER regulations, the employer is under a legal obligation to make sure that all lifting operations are done more safely. An employer must hire a competent individual to plan, supervise, and carry out lifting operations.

Under the LOLER regulations, an employer must adhere to the following guidelines:

- Conduct risk assessment

- Provide adequate training to the equipment user

- Supervise the use of lifting equipment

- Ensure that the equipment is in good shape

Violating these guidelines can lead to serious legal implications.

The following are some of the key requirements under the LOLER regulations:

- Choose the right lifting equipment

- Mark the equipment appropriately

- Inspect and certify the equipment the right way

- Conduct regular LOLER risk assessments. Provide clear safety precautions

- Train equipment handlers before allowing them to use it.

- Ensure that there is a record-keeping

Importance

LOLER which testing is important in several ways. They include:

Legal Requirement

The law requires all lifting equipment, including chandelier winches, to be tested under the LOLER regulations. As a business owner, you must ensure you have fulfilled all the LOLER testing requirements. You must provide adequate training and conduct necessary.

Safety

LOLER inspections are important because they ensure the safety of all employees. Conducting necessary testing ensures that the winches are working optimally, which minimizes accidents. These inspections can detect faults, malfunctions, etc.

Safe Working Load

LOLER inspections are also designed to protect your winches from excessive loads. They help you decide the right weight your winch can bear, which improves the operational efficiency of your equipment.

The Bottom-Line

Workplace safety has become a major concern across different sectors. From warehousing to lighting installation, learning workplace safety is an important aspect. For instance, it’s important to understand LOLER testing for winches, how it’s done, and its importance. The above guide contains everything you need to know about LOLER testing for chandelier winches and how you can optimize your safety while handling lifting equipment.